Time to read: 6 min

What is CNC Milling?

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape or part. This process is widely used in the manufacturing industry for its precision, repeatability, and ability to produce complex geometries.

History of CNC Milling

The history of CNC milling dates back to the 1950s when the first numerical control (NC) machines were developed. These early machines used punched tape to control the movement of the cutting tool. Over the years, advancements in technology have led to the development of more sophisticated CNC machines, which are now capable of producing parts with extremely high precision and accuracy.

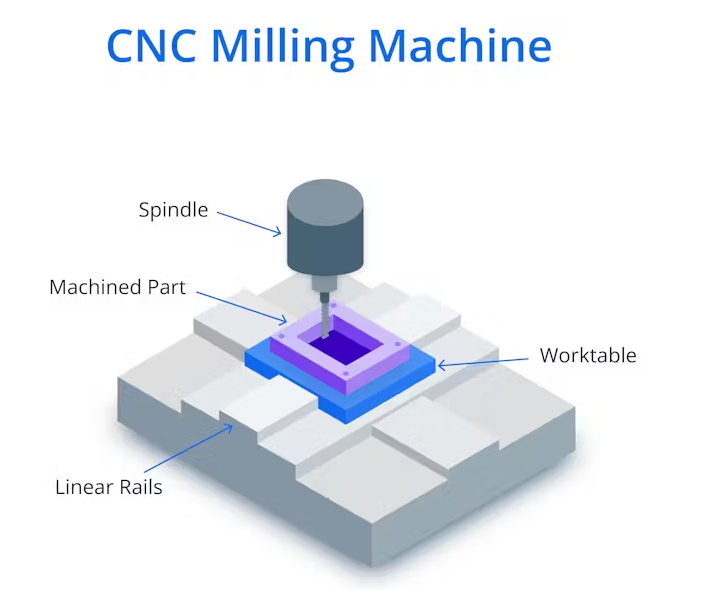

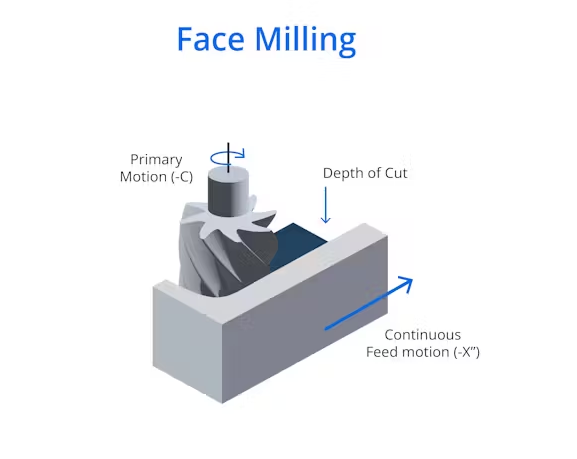

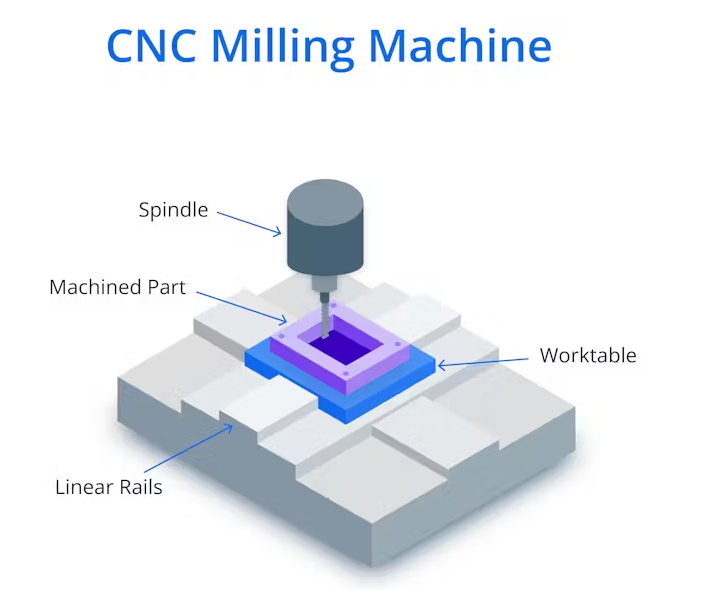

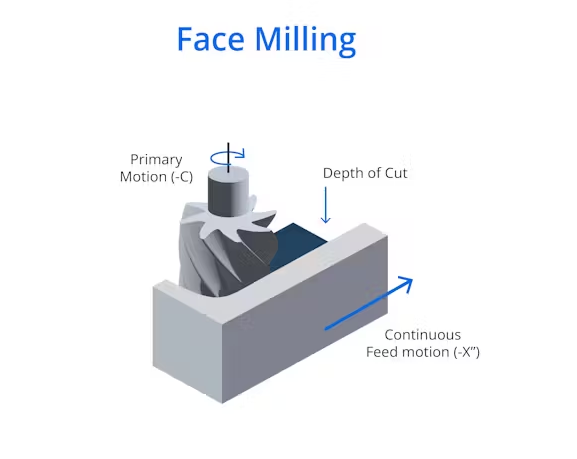

How CNC Milling Works

CNC milling works by using a rotating cutting tool to remove material from a workpiece. The process is controlled by a computer program that dictates the movement of the cutting tool and the speed at which it operates. The workpiece is securely clamped in place, and the cutting tool moves along three axes (X, Y, and Z) to create the desired shape.

Applications of CNC Milling

CNC milling is used in a variety of industries, including:

- Aerospace: For the production of aircraft components and parts.

- Automotive: For the manufacturing of engine parts, transmission components, and other automotive parts.

- Medical: For the creation of surgical instruments and medical implants.

- Consumer Goods: For the production of consumer products such as toys, electronics, and household items.

Benefits of CNC Milling

The benefits of CNC milling include:

- Precision: CNC milling can produce parts with extremely high precision and accuracy.

- Repeatability: The process is highly repeatable, ensuring consistent quality in every part produced.

- Complex Geometries: CNC milling is capable of producing complex geometries that would be difficult or impossible to achieve with traditional machining methods.

- Efficiency: The process is highly efficient, reducing waste and production time.

Summary

CNC milling is a critical process in modern manufacturing, offering precision, repeatability, and the ability to produce complex geometries. At UnoFactory, we specialize in CNC milling and offer a range of services to meet your specific needs. For more information on how UnoFactory can assist with your CNC milling requirements, contact us today.

Disclaimer

The content provided is for informational purposes only. UnoFactory makes no representation or warranty, expressed or implied, regarding the accuracy, completeness, or validity of the information. Performance parameters, geometric tolerances, specific design features, quality, and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through UnoFactory’s network. Buyers are responsible for defining the specific requirements for their parts. Please refer to our terms and conditions for more information.