Time to read: 6 min

Understanding Thread Milling

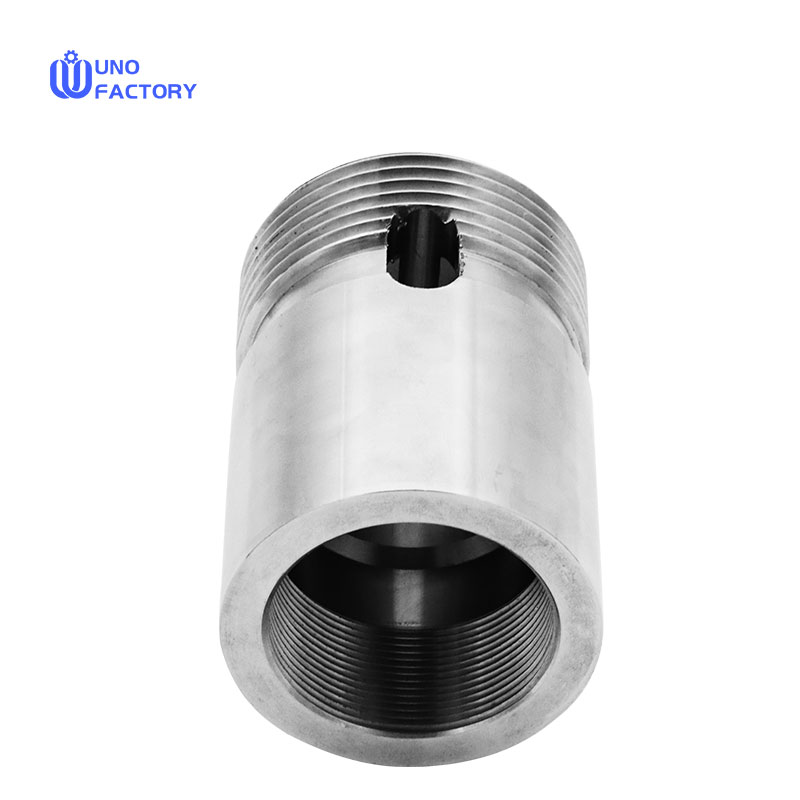

Thread milling is an adaptable method employed for threading a wide spectrum of hole sizes, especially those with larger diameters. Unlike tapping, which uses a tool matching the hole size, thread milling utilizes a smaller tool that moves circularly around the hole’s circumference to cut threads.

Thread milling is a technique for cutting threads into a part or workpiece with limited contact, particularly for internal threads where the cutting tool's diameter is smaller than the hole. This method contrasts with tapping, as it doesn’t require full circumference contact with the workpiece, allowing for threading in materials with poor machinability or in large diameter holes where tapping falls short.

The Mechanics of Thread Milling

Thread milling employs a toothed cutting tool that rotates rapidly. The spindle, holding the tool, moves in a circular path in the horizontal x-y plane, coupled with a slow vertical z-axis movement. Each rotating tooth of the tool cuts a thread that progresses in the z direction through the hole. This process can be completed in a single pass but is often done in two vertical passes for precision.

Distinguishing Thread Milling from Other Milling Techniques

Thread milling is one of many milling techniques, each with specific tools designed for material removal and workpiece shaping. What sets thread milling apart is the use of toothed cutting tools and the requirement for a CNC milling machine to coordinate three movements: constant rotational speed, vertical progression along the z-axis, and circular motion in the x-y plane.

Varieties of Thread Milling Cutters

The diversity in thread milling cutters mirrors the variety of holes found in components, catering to different applications:

-

Straight Flute Thread Mills: These have straight flutes between cutting teeth for chip evacuation. The simultaneous engagement of teeth with the workpiece can limit speed and feed rates, making them suitable for easier-to-machine materials.

-

Helical Flute Thread Mills: Featuring multiple rows of teeth and helically arranged flutes, these cutters reduce cutting pressure by staggering tooth engagement, ideal for high-speed thread milling.

-

Single Profile Thread Mills: With a single tooth for cutting threads and multiple flutes, these cutters require lower torque and generate less heat, making them versatile for difficult-to-machine materials.

Advantages of Thread Milling

Thread milling offers several benefits over traditional tapping, such as the ability to create various thread types with a single tool, lower power and torque requirements, reduced tool wear, and applicability to difficult materials.

Disadvantages of Thread Milling

Despite its advantages, thread milling is slower than tapping in some cases and requires more sophisticated, and thus costly, machinery like CNC mills.

Selecting the Right Thread Milling Cutters with unofactory

unofactory plays a pivotal role in assisting customers in sourcing the right thread milling cutters for their specific needs. Factors influencing cutter selection include batch size, hole diameter, hole depth, and material properties.

The Impact of Choosing the Right Thread Milling Cutters

The appropriate selection of thread milling cutters is crucial for cost-effective production, as incorrect choices can lead to increased costs, downtime, and scrapped parts.

Thread Milling Process with unofactory

unofactory aids in understanding the application, selecting the optimal thread mill cutting tool, and conducting CNC programming. It recommends using CAD/CAM software for precision and suggests setting up trial pieces to test tool-path feeds and speeds before full production.

Tips for Effective Thread Milling

Optimal thread milling requires attention to tool wear, slower cutting speeds, sufficient coolant flow, secure workpiece clamping, and adjustments to the tool's approach to extend tool life.

How unofactory Can Help

unofactory provides a broad range of manufacturing capabilities, including CNC machining, and is ready to provide instant quotes for your precision thread milling needs.