Time to read: 6 min

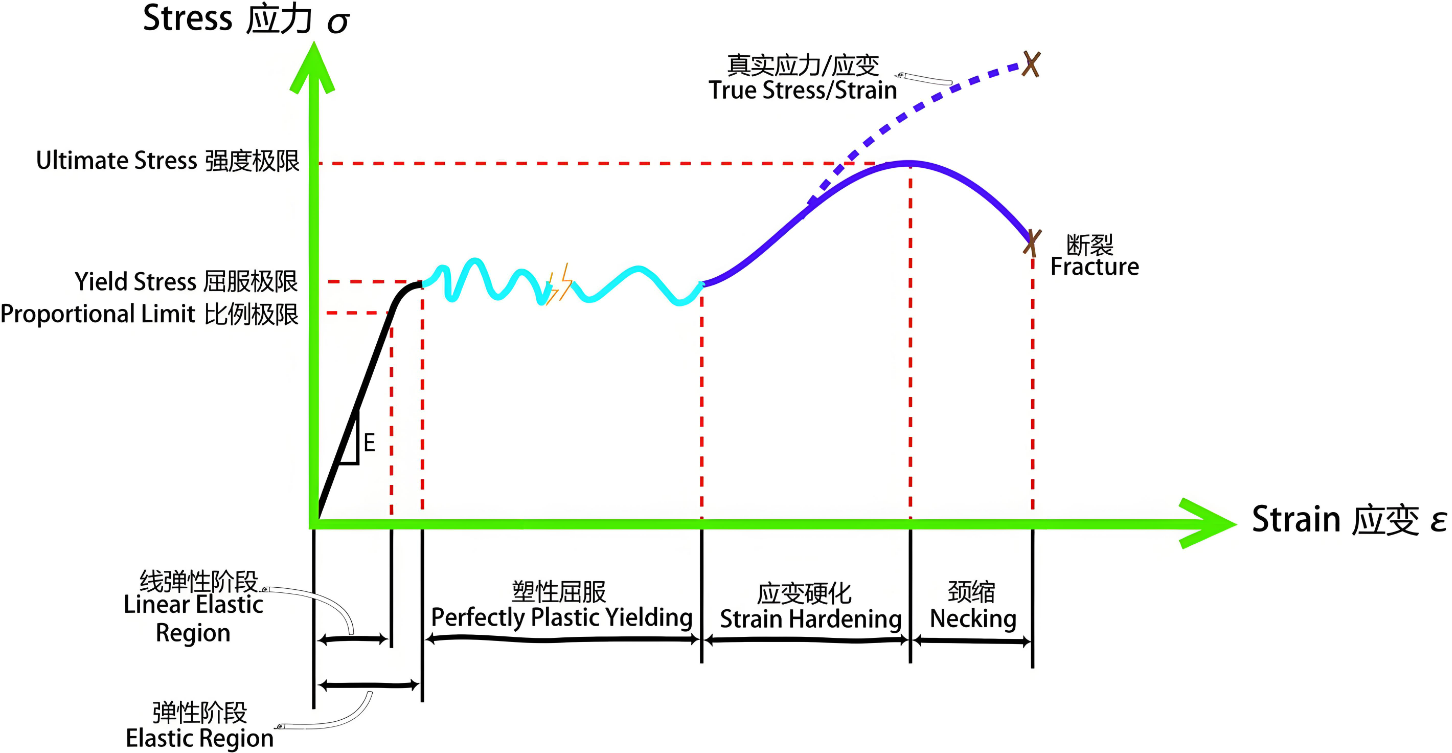

In the field of materials science and engineering, understanding how materials respond to forces is crucial. This response is often characterized by the stress-strain curve, a graphical representation that illustrates the relationship between the stress applied to a material and the resulting strain. This article will explore the stress-strain curve, its significance, and how it's used to evaluate material properties.

What is a Stress-Strain Curve?

A stress-strain curve is a graphical plot that shows the relationship between the stress applied to a material and the material's corresponding strain response. It's a valuable tool for understanding a material's mechanical behavior under various conditions.

Key Points of the Stress-Strain Curve

- Elastic Region: At low stresses, materials deform elastically, meaning they return to their original shape once the stress is removed. This region is linear, and Hooke's Law applies.

- Yield Point: The point at which the material begins to deform plastically, not returning to its original shape even after the stress is removed.

- Ultimate Tensile Strength: The maximum stress a material can withstand before it breaks.

- Plastic Region: Beyond the yield point, the material deforms plastically, with strain increasing rapidly even with little increase in stress.

- Necking: In ductile materials, a localized reduction in cross-sectional area occurs just before failure.

Importance of the Stress-Strain Curve

The stress-strain curve is crucial for several reasons:

- Material Selection: It helps engineers select materials with the desired properties for specific applications.

- Design Optimization: It allows for the optimization of part design to ensure safety and reliability under expected stress conditions.

- Quality Control: It provides a means to assess the mechanical properties of materials, ensuring they meet performance standards.

Stress and Strain in 3D Printing

In the context of 3D printing, understanding the stress-strain behavior of materials is vital:

- Material Properties: Different 3D printing materials, such as PLA, ABS, and nylon, have distinct stress-strain curves that affect their printability and end-use performance.

- Print Orientation: The orientation of a printed part can influence its mechanical properties, particularly its strength and ductility.

- Infill and Layer Height: These printing parameters can significantly affect the stress-strain behavior of the final part.

Applications of Stress-Strain Curves

The stress-strain curve is applied across various industries:

- Automotive: For designing components that can withstand high stresses and strains during operation.

- Aerospace: To develop materials and structures that are lightweight yet strong enough to handle the rigors of flight.

- Construction: To ensure the structural integrity of buildings and infrastructure under various loads.

Conclusion

The stress-strain curve is a fundamental concept in materials science, providing insights into how materials behave under stress. At Unofactory, we leverage this knowledge to ensure that the materials we use in our 3D printing and other manufacturing processes meet the highest standards of performance and reliability.

For expert guidance on material selection and stress-strain behavior, contact Unofactory today.