Time to read: 6 min

Understanding SLA and FDM 3D Printing

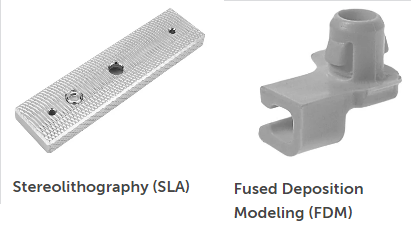

SLA, a photopolymer-based 3D printing technology, constructs parts layer by layer using a UV laser to cure liquid resin. FDM, on the other hand, is an extrusion-based process that builds parts by depositing melted plastic filament onto a build plate.

SLA 3D Printing: Definition and Comparison to FDM

SLA 3D printing, invented by Charles Hull, uses a UV laser to solidify a photosensitive resin, creating high-detail parts with excellent surface finish. In contrast, FDM 3D printing extrudes plastic filament through a heated nozzle, offering a wider range of materials and generally stronger parts.

Advantages of SLA 3D Printing Over FDM

- Resolution and Surface Finish: SLA offers superior resolution and can produce parts with a smoother surface finish compared to FDM 3D printing.

- Printing Speed: SLA printers can print parts more quickly than FDM printers without compromising on quality.

Disadvantages of SLA 3D Printing Compared to FDM

- Cost: SLA printing is generally more expensive than FDM 3D printing, both in terms of materials and equipment.

- Part Strength: Parts produced by SLA tend to be weaker than those made through FDM 3D printing due to the nature of photopolymers being less durable than thermoplastics.

FDM 3D Printing: Definition and Comparison to SLA

FDM 3D printing, developed by Scott Crump, is a widely accessible technology that extrudes melted plastic through a nozzle, building parts layer by layer. It is known for its simplicity, affordability, and versatility in material options.

SLA vs. FDM 3D Printing: Detailed Comparisons

- Technology: SLA uses a UV laser for curing resin, while FDM 3D printing relies on extruding plastic filament.

- Materials: SLA is limited to photopolymer resins, whereas FDM offers a broader range of thermoplastic materials, including flexible options.

- Applications: SLA is suited for high-detail models and prototypes, whereas FDM 3D printing is ideal for functional parts and applications requiring strength.

- Build Volume: FDM printers often have larger build volumes compared to SLA printers.

- Surface Finish: SLA produces parts with a better surface finish than FDM 3D printing, which typically requires post-processing to achieve a smooth finish.

- Cost: FDM 3D printing is more cost