Time to read: 6 min

In the realm of precision manufacturing, GD&T (Geometric Dimensioning and Tolerancing) symbols play a pivotal role. This article delves into the intricacies of GD&T symbols, their application, and how they streamline the design and manufacturing process. Discover how GD&T symbols can elevate your design standards and ensure optimal part performance.

The art of manufacturing hinges on precise design, and GD&T symbols are the language that enables this precision. Engineers worldwide use GD&T symbols to define and communicate the geometric requirements of a part. This article will guide you through the essential aspects of GD&T symbols, their significance, and how they can enhance your design process.

What is GD&T?

GD&T is a system of symbols and standards used by engineers to communicate manufacturing information clearly and concisely. GD&T symbols serve multiple purposes, including:

- Defining production and inspection processes effectively.

- Ensuring that mating parts fit together seamlessly.

- Indicating the maximum allowable variations without compromising part functionality.

- Acting as a universal language in the manufacturing industry, ensuring clear communication across different teams and regions.

Developed by Stanley Parker in 1938, GD&T has become an indispensable tool in the manufacturing sector, particularly for parts requiring CNC machining services with tight tolerances.

Importance of GD&T Symbols

Despite traditional methods of determining tolerances and dimensions, GD&T symbols offer unique advantages:

Enhanced Assembly

GD&T symbols ensure that individual parts, designed with precision, integrate flawlessly when assembled. This system guarantees that parts will fit well within larger components, maintaining the overall efficiency of the assembly.

Universally Understandable

GD&T symbols are universally recognized, facilitating clear communication among engineers globally. This standardization simplifies the designer's intent, ensuring that it is accurately understood and implemented.

Time and Cost Savings

GD&T symbols help eliminate the need for redesign and rework by ensuring that the design is accurate from the outset. This reduces waste and streamlines the manufacturing process, saving both time and resources.

How do GD&T Symbols Work?

GD&T symbols operate on the principle of specifying required dimensions and tolerance values. These symbols communicate the design intent, ensuring that parts fit their intended roles perfectly.

GD&T Symbols Explained

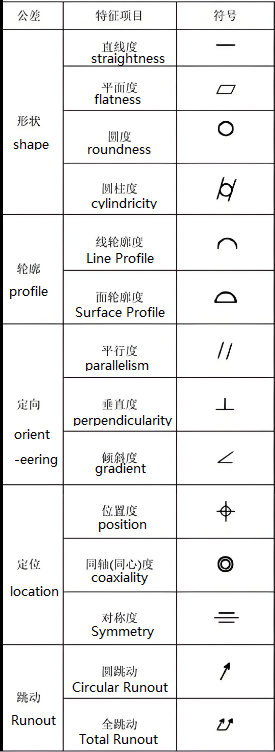

GD&T symbols are categorized into five main groups, each with distinct symbols for different geometric controls:

Form Controls

These symbols specify the shape requirements of a part, including straightness, flatness, circularity, and cylindricity.

Profile Controls

Profile controls describe the three-dimensional tolerance zone around a surface, ensuring that the surface profile and line profile meet the specified tolerances.

Orientation Controls

Orientation controls include angularity, perpendicularity, and parallelism, which define the angular relationships between features.

Location Controls

Location controls, such as position, concentricity, and symmetry, use linear dimensions to define the exact location of features.

Runout Controls

Runout controls indicate the acceptable variation of a feature relative to datums, including circular runout and total runout.

Feature Control Frame

The feature control frame is a critical component of GD&T symbols, controlling the features of your design and ensuring they meet the specified requirements.

Conclusion

GD&T symbols are a modern and efficient method for describing the dimensions and tolerances of your design. They are superior to traditional plus/minus tolerancing methods, ensuring that parts designed using GD&T symbols fit perfectly and function as intended.

At Unofactory, we understand the importance of precision in manufacturing and offer a wide range of services to meet your GD&T requirements. Our expertise in CNC machining and adherence to GD&T standards ensure that your parts are manufactured to the highest quality standards.

For more information on how Unofactory can assist with your GD&T needs or to get a quote, visit our website today.

Disclaimer

The content provided is for informational purposes only and should not replace professional advice. While we strive to keep the information accurate and up-to-date, we make no warranties about the completeness or accuracy of the information.

Contact Unofactory for Your GD&T Needs

At Unofactory, we specialize in precision manufacturing and understand the importance of adhering to GD&T standards. Our team of experts is ready to assist you with your GD&T requirements, ensuring that your parts are manufactured to the highest quality standards.