Time to read: 6 min

In the realm of design engineering, the distinction between fillets and chamfers is crucial. Often confused, these two features serve opposing purposes in part design. This article will clarify the concepts of fillets and chamfers, their differences, and guide you on when to use each for optimal part performance and manufacturing success with unofactory.

The importance of understanding fillets and chamfers in engineering design cannot be overstated. The choice between them can significantly impact part performance, stress distribution, and manufacturing outcomes.

-

What is a Fillet?

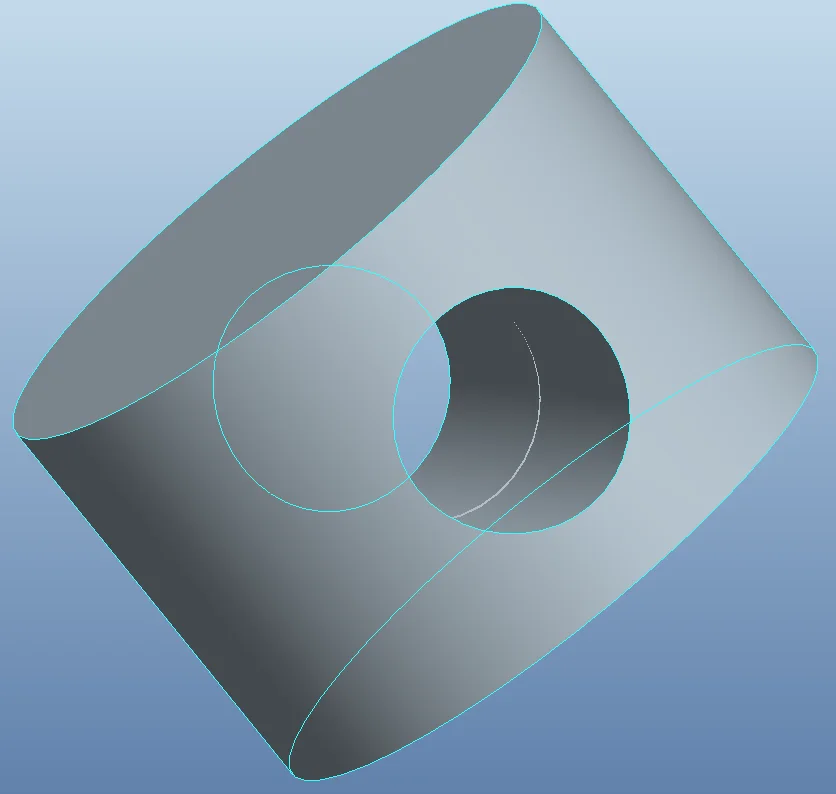

- In mechanical engineering, a fillet refers to the rounded transition between two surfaces, either internally or externally. Fillets come in three types: miter, concave, and convex. They are essential for reducing stress concentration and preventing rapid deformation in parts.

-

What is a Chamfer?

- A chamfer is the beveled or angled edge of a part, the direct opposite of a fillet. Chamfers are straight with a sharp angle, focusing stress in specific areas and are ideal for designs requiring high-stress concentration edges.

-

When to Use a Fillet or Chamfer?

- Choosing the right feature is vital for part longevity and efficiency. This section will explore the factors that influence the decision between using a fillet or chamfer in your design.

Differences Between Fillet and Chamfer

| Feature | Fillet | Chamfer |

|---|---|---|

| Purpose | To distribute stress over a larger area, reducing stress concentration. | To concentrate stress at specific points, useful for high-stress applications. |

| Appearance | Rounded edges, both internal (concave) and external (convex). | Beveled or angled edges, providing a sharp transition. |

| Stress Distribution | Evenly distributes stress, preventing deformation. | Concentrates stress, which can lead to deformation if not designed correctly. |

| Safety | Safer for handling due to rounded edges. | Sharp edges can cause injury during handling. |

| Manufacturing Cost | Generally more expensive due to the complexity of creating rounded edges. | More cost-effective as beveled edges are easier to create. |

Factors to Consider When Choosing Between a Fillet and Chamfer

-

Machining Time and Cost

- For quick manual designs, chamfers are faster and more cost-effective. However, with CNC machining, the difference in time is negligible.

-

Aesthetics

- Fillets enhance the visual appeal of a design, making them a preferred choice for industrial designers.

-

Rust Prevention

- Fillets can prevent accelerated rusting by allowing for even distribution of coatings like paint, providing better protection against rust compared to chamfers.

-

Stress Management

- Fillets are superior for designs requiring even stress distribution along edges.

-

Hole Functionality

- If a hole is intended for pin insertion or driving screws and bolts, chamfers are the better option, facilitating smoother pin movement and easier fastening.

Conclusion

Understanding the nuances between fillets and chamfers is essential for engineers to make informed decisions that enhance part efficiency, reduce costs, and extend part lifespan. At unofactory, we specialize in design engineering and part manufacturing, offering expert advice and top-tier services to ensure your designs excel in the manufacturing stage.

For your complex CNC machining projects, trust unofactory for 3, 4, and 5-axis milling, quality inspection, and material certifications, all at competitive industry prices.