Time to read: 6 min

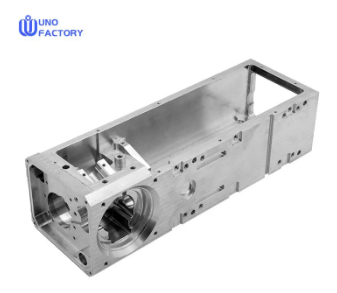

- CNC Milling and Turning: CNC machining involves automated cutting machines that remove material with a rotating spindle head. Turning spins material against a stationary tool to achieve the desired shape. These processes work well with a range of materials, including plastic, aluminum, stainless steel, and titanium.

- How It Works: CNC turning uses CNC lathes or multi-axis turning centers. Modern CNC technologies support up to 5 axes, enabling precise cutting for more detailed parts.

- Materials: Aluminum, brass, bronze, copper, steel, stainless steel, titanium, and zinc alloys.

- Industries: Aerospace, automotive, consumer products, electronics, industrial, medical, and robotics.

- How It Works: Extrusion involves pushing heated metal or plastic through a die to create a net shape. It is ideal for high volumes of parts with constant cross-sections.

- Materials: Primarily aluminum alloy for metals and polyethylene for plastics.

- Industries: Automotive, aerospace, construction, and consumer products.

- How It Works: Metal casting involves pouring liquid metal into a mold, where it hardens into the desired shape. Modern casting is precise and automated.

- Materials: Aluminum, magnesium, copper alloys, zinc, steel, and other metals.

- Industries: Automotive, consumer electronics, and industrial equipment.

- How It Works: Die casting uses steel molds and low-melting-point metals to create complex parts. It is ideal for high-volume production.

- Materials: Aluminum, zinc, and magnesium.

- Industries: Automotive, electronics, and consumer goods.

- How It Works: MIM uses a polymer-metal mix to create parts. The material is injected into a mold and then sintered to remove the polymer.

- Materials: Powdered metals such as stainless steel, titanium, and other alloys.

- Industries: Medical, aerospace, automotive, and defense.

- How It Works: Forging involves heating and shaping metal parts using high-impact machines. It produces strong, durable parts.

- Materials: Stainless steel, aluminum, and bronze.

- Industries: Automotive, aerospace, and industrial tools.

- How It Works: Sheet metal fabrication involves cutting and bending metal sheets to create parts. Stamping is used for high-volume production.

- Materials: Aluminum, copper, and steel.

- Industries: Electronics, automotive, and industrial equipment.

- How It Works: Metal 3D printing uses lasers to create parts layer by layer. It is ideal for complex geometries and prototypes.

- Materials: Stainless steel, titanium, Inconel, copper, and aluminum powders.

- Industries: Aerospace, medical, and industrial components.