Time to read: 6 min

Enhancing 3D-Printed Parts with Acetone Vapor Smoothing

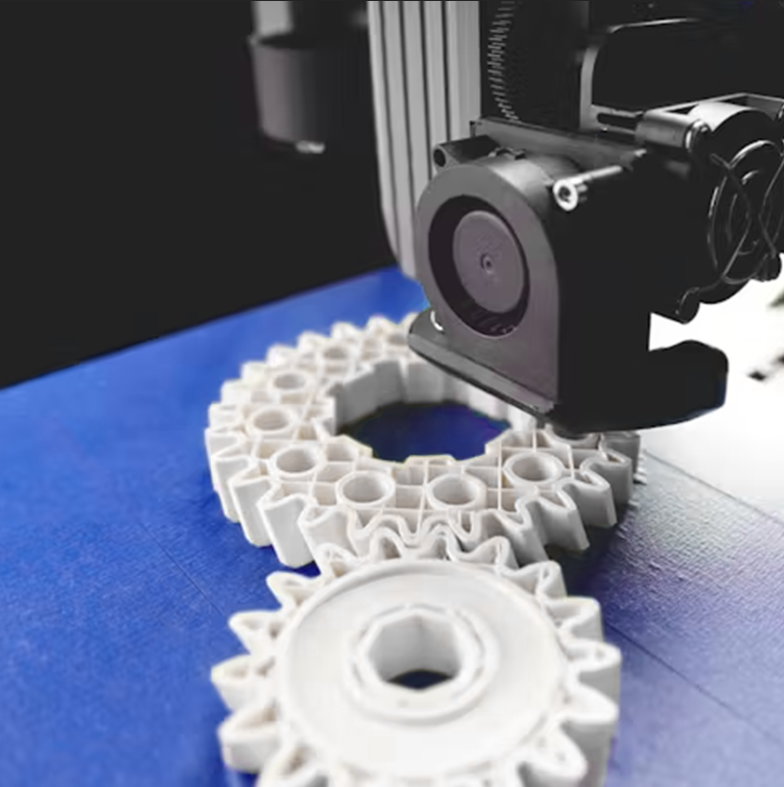

Acetone vapor smoothing is a post-processing technique used to enhance the surface finish of 3D-printed polymers, particularly those produced using Fused Deposition Modeling (FDM). This method is especially effective for smoothing out rough surfaces and improving the overall appearance of 3D-printed parts.What is Acetone Vapor Smoothing?

Acetone vapor smoothing is a post-manufacturing process designed to eliminate surface imperfections on 3D-printed parts. It works by exposing compatible materials—such as ABS, ASA, PMMA, HIPS, and PC—to acetone vapors. The vapors dissolve the outermost layer of the material, creating a smooth and glossy finish. This technique is particularly useful for FDM-printed parts, which often have uneven surfaces due to layer lines and rough edges.

The Process of Acetone Vapor Smoothing

To perform acetone vapor smoothing, follow these steps:Preparation: Clean and sand the 3D-printed part to remove any major imperfections or support structures. Ensure the part is free from dust and debris.

Setting Up the Vapor Chamber: Place the part in a transparent, non-reactive container (such as glass) with a base layer of acetone-soaked materials (e.g., paper towels). Ensure the part is elevated and not in direct contact with the liquid acetone.

Exposure to Vapor: Allow the acetone vapors to rise and interact with the part’s surface. Monitor the process closely, as the smoothing time can vary based on the part’s size, material, and desired finish.

Drying: Once the desired smoothness is achieved, carefully remove the part and allow it to dry in a well-ventilated area. This can take anywhere from a few hours to a couple of days.

Benefits of Acetone Vapor Smoothing

Improved Aesthetics: Acetone vapor smoothing creates a smooth, glossy finish, eliminating visible layer lines and enhancing the part’s overall appearance.

Enhanced Mechanical Properties: The process strengthens interlayer adhesion, particularly in the z-axis, resulting in a more durable part.

Uniform Smoothing: Unlike other methods, acetone vapor smoothing provides a consistent finish across all surfaces of the part.