Time to read: 6 min

Zinc die casting is a manufacturing process renowned for producing robust and precise metal components. This article explores the process, advantages, and applications of zinc die casting, offering insights into why it's a preferred choice in various industries.

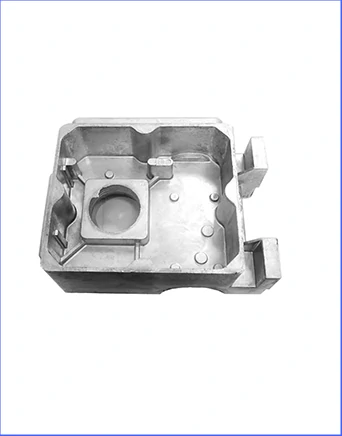

Zinc Die Casting: A Manufacturing Marvel

Zinc die casting is a process where molten zinc alloys are injected into a die casting mold. Known for its low melting point, zinc is ideally suited for the hot chamber die casting process, which is both efficient and cost-effective.

The Zinc Die Casting Process

The process of zinc die casting involves several key steps, from preparing the die to cooling and ejection of the final part. Each step is meticulously executed to ensure the production of high-integrity components.

Advantages of Zinc Die Casting

Zinc die casting offers a multitude of benefits, including:

- Easy Assembly: With parts cast as single units, assembly is streamlined.

- High Precision with Thin Walls: Zinc's strength allows for thinner walls, reducing material use and cost.

- Superior Mechanical Properties: Zinc alloys exhibit excellent strength, corrosion resistance, and durability.

- Complex Geometries: Zinc's properties make it ideal for intricate part designs.

- Longer Tool Life: The low abrasiveness and melting point of zinc extend the life of molds.

- Faster Production Rates: Zinc's rapid solidification rate increases cycle rates significantly.

Zinc Alloys for Die Casting

Various zinc alloys are used in die casting, each with distinct properties. Common alloys include Zamak 2, Zamak 3, Zamak 7, ZA-8, ACuZinc5, EZAC, and ZA-27, each chosen based on the specific requirements of the part being produced.

Applications of Zinc Die Casting

Zinc die castings are used across diverse industries:

- Automotive Industry: For interior and engine components, leveraging zinc's strength.

- Electronics: In the production of components like energy regulators and switches, capitalizing on dimensional stability.

- Home Appliances: For parts that require structural integrity and durability.

- Mechanical Sector: In engines and machinery, where creep resistance and hardness are critical.

Conclusion

Zinc die casting is a powerful method for creating strong, durable parts with complex geometries. It is a cost-effective solution for high-volume production, offering a wide range of applications in various industries.