Time to read: 6 min

Rivets play a crucial role in various manufacturing industries, providing reliable fastening solutions for a wide range of applications. This guide offers a detailed overview of different rivet types, their common uses, and the factors to consider when selecting the right rivet for your project.

Understanding Rivets: A Basic Introduction

A rivet is a mechanical fastener characterized by a head and a tail, typically used to join two components permanently. Made from materials like aluminum or steel, rivets are installed using unique methods that ensure a secure and lasting connection.

How Rivets Function

Rivets are installed by drilling a hole in the components to be joined. The rivet is then placed in the hole, and its tail is deformed, creating a new head on the other side, thus securing the joint.

Materials for Rivet Manufacturing

Rivets can be manufactured from diverse金属材料, including steel, stainless steel, aluminum, brass, and copper, each chosen based on the specific requirements of the application.

Types of Rivets and Their Uses

Solid Rivets

- The most common type, used for critical safety and reliability applications, such as aircraft structures.

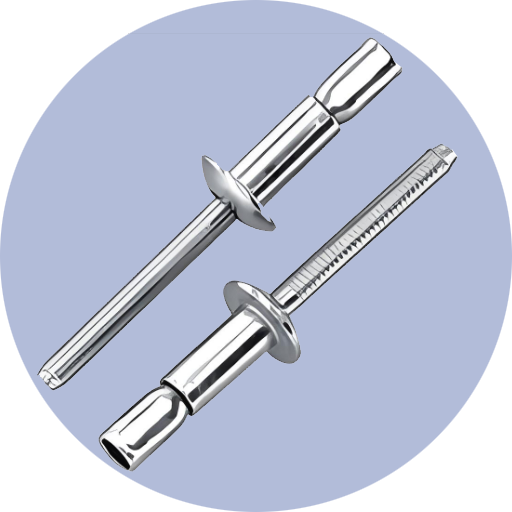

Blind Rivets (Pop Rivets)

- Tubular fasteners with a central mandrel, suitable for situations where access to the rear side of a joint is limited.

Tubular Rivets

- Partially hollow rivets with various configurations, popular in commercial applications due to their ductility and low-strength properties.

Split Rivets

- Ideal for joining softer materials like leather, plastic, and wood, often used in home repairs.

Flush Rivets (Countersink Rivets)

- Used on external surfaces for a streamlined appearance and reduced aerodynamic drag, commonly found on aircraft exteriors.

Self-Piercing Rivets

- Do not require pre-drilled holes, featuring a beveled end that pierces the material, forming a tight seal.

Friction Lock Rivets

- Similar to expanding bolts, these rivets snap below the surface under tension, originally used in aerospace for light aircraft repairs.

Rivets in Various Industries

- Aircrafts: Essential for joining aluminum alloys and ensuring structural integrity.

- Jewelry: Used as a cold joining technique without the need for soldering.

- Construction: Common in applications like fiberglass roofing, gutters, and furniture joints for durability.

Conclusion

Rivets offer a robust alternative to traditional fasteners, providing efficient and reliable connections in various applications. Choosing the appropriate type of rivet is key to achieving the best results in your project.

Unofactory specializes in providing high-quality CNC machining services for metal rivets, catering to the specific needs of prototyping and production. Our expert technicians ensure fast lead times and precise outcomes.

When you upload your design file to our platform, our system conducts an automated DfM analysis and provides an instant quote. For exceptional metal rivets and CNC machining services, contact Unofactory.