Time to read: 6 min

In today's industrial manufacturing sector, precise part marking is not only crucial for quality control but also key to supply chain management. This article will explore the latest part marking technologies, including laser engraving, silk screening, laser marking, and inkjet printing, and how they help businesses ensure part traceability and anti-counterfeiting.

The Importance of Part Marking

Part marking is an indispensable part of industrial manufacturing, ensuring the traceability of parts from production to the end-use phase. Whether in the automotive, aerospace, electronics, or medical industry, part marking plays a vital role.

Overview of Part Marking Technologies

With technological advancements, various part marking technologies have emerged to meet the needs of different industries. Here are some of the main marking technologies:

Laser Engraving

Laser engraving is a non-contact method that physically removes the surface of the component with a laser beam, revealing a distinct image or text. Known for its speed and precision, this technique is particularly suitable for marking on 3D printed parts.

Silk Screening

Silk screening is a cost-effective and easy method, popular in metal fabrication. It involves applying design elements to metal pieces through the use of stencils and ink, suitable for a wide variety of materials, including bare metal and stainless steel.

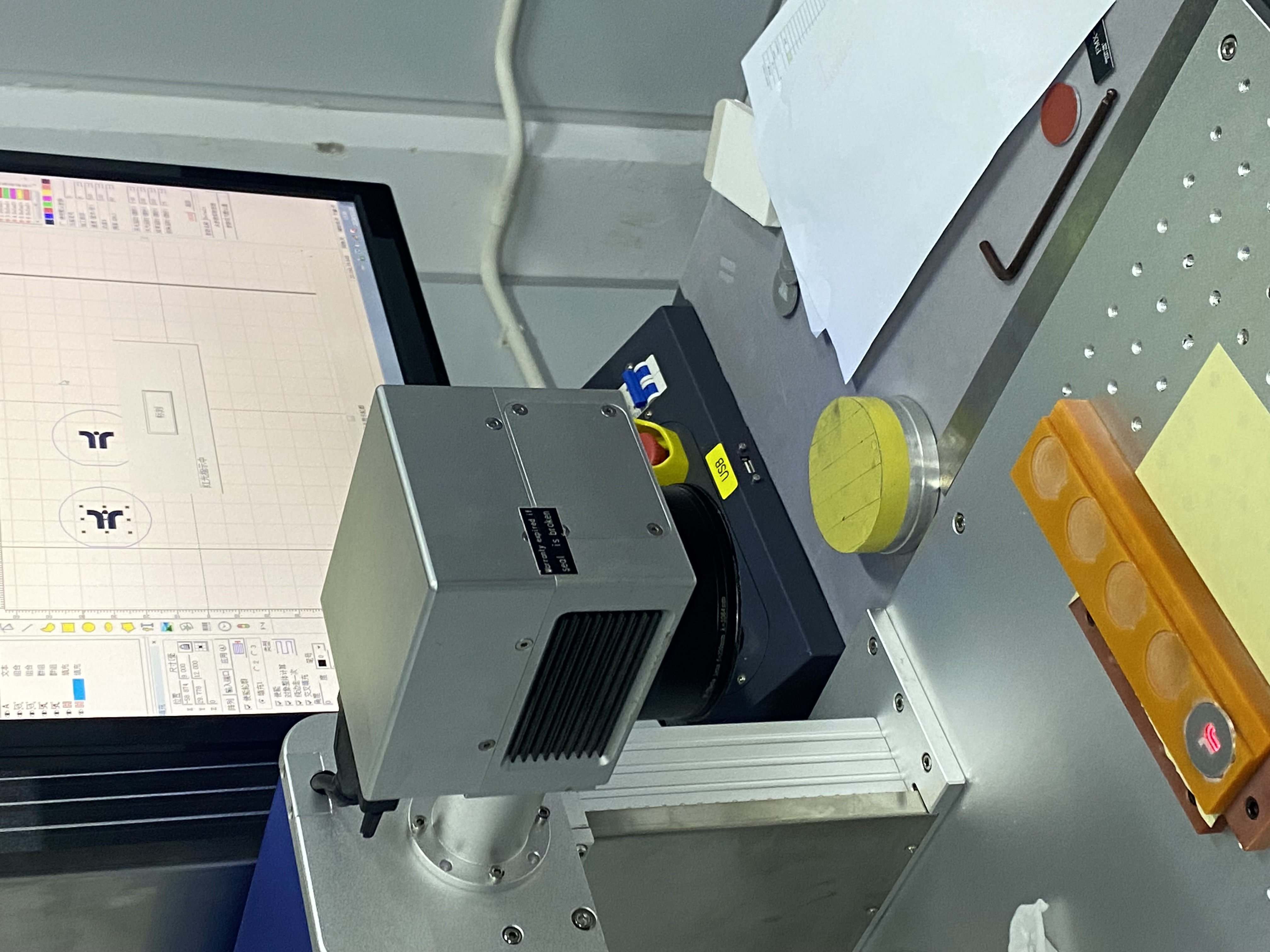

Laser Marking

Laser marking slightly alters the properties and appearance of the component's surface through the interaction of laser beams with the material. Popular in the medical industry, this technique is ideal for marking titanium and stainless steel parts.

Inkjet Printing

Inkjet printing is a non-contact technique effective for multiple products of varying shapes and sizes. Modern inkjet printers use images from electronic files, placing them directly onto the part to be marked.

Pros and Cons of Part Marking

Each part marking technology has its strengths and limitations. For instance, laser engraving and marking are fast and cost-effective, but inkjet printing may have higher running costs and require regular cleaning of the print heads.

Conclusion

Choosing the right part marking technology requires consideration of several factors, including the content of the marking, its location, the size and geometry of the part, the form and function of the product, and the budget. Unofactory offers customized part marking solutions to help businesses improve production efficiency and product quality.