Time to read: 6 min

In the realm of CNC machining, the choice of material is pivotal to the success of a project. This article serves as a comprehensive guide, detailing the factors to consider and the materials available for CNC machining. We explore the properties and applications of various materials, providing clarity to help you make the right selection for your specific needs.

Introduction to CNC Machining Materials

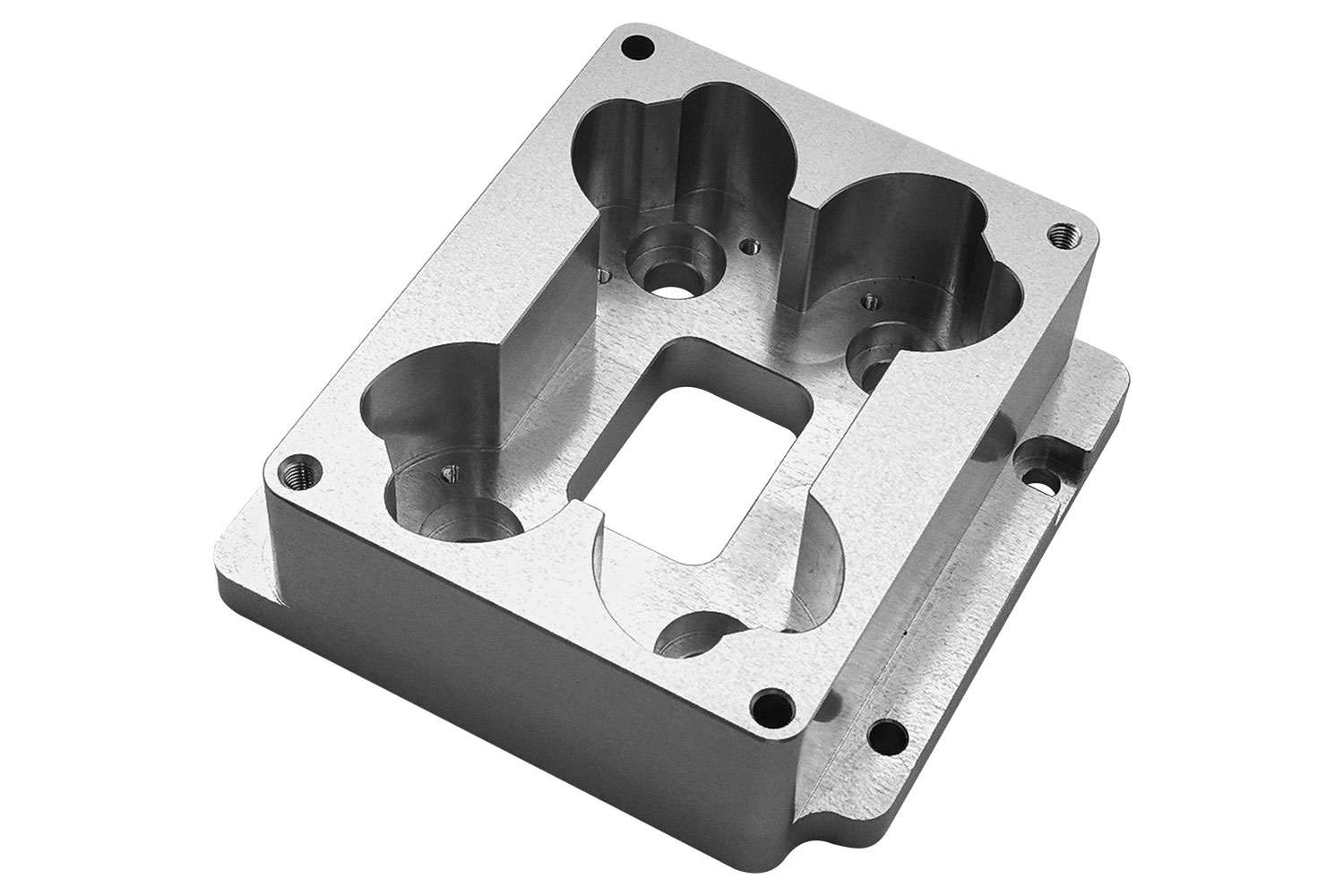

CNC machining is a cornerstone of the manufacturing industry, underpinning the production of complex components for industries such as aerospace, medical devices, and electronics. The choice of material is crucial, balancing strength, machinability, and application-specific requirements.

Factors Influencing Material Selection

- Machining Environment: The conditions under which machining occurs can affect material performance and tool life.

- Part Weight: Material density impacts part weight, influencing cost, performance, and manufacturability.

- Heat Resistance: Materials must withstand high temperatures without deformation during machining processes.

- Electrical Conductivity and Magnetic Properties: Important for heat dissipation and the impact on the cutting process.

- Hardness: Affects machinability, tool wear, and the efficiency of the machining process.

- Surface Finish: Influences performance, lifespan, and aesthetics of the final product.

- Aesthetics: Particularly important for high-end retail products and applications where appearance is a factor.

- Application: The intended use of the CNC-machined part dictates material properties and selection.

- Budget: Material and machining costs must align with the project budget while maintaining quality.

The Best Materials for CNC Machining Projects

-

Metal CNC Materials: Known for their strength, hardness, thermal resistance, and electrical conductivity.

- Aluminum: Versatile with a good strength-to-weight ratio, easy to machine.

- Stainless Steel: Offers high strength, toughness, and corrosion resistance, but more challenging to machine.

- Carbon and Alloy Steel: Excellent strength and machinability, but not inherently corrosion-resistant.

- Brass: Excellent machinability and corrosion resistance, with good thermal and electrical conductivity.

- Copper: Known for its conductivity but challenging to machine due to high malleability.

- Titanium: Lightweight and strong with good heat conductivity, but difficult and expensive to machine.

- Magnesium: Combines strength with low weight, but flammable and less corrosion-resistant.

-

Plastic CNC Materials: Offer a range of properties and are generally easier to machine than metals.

- Acetal (POM): Versatile with excellent fatigue and impact resistance, easy to machine with great dimensional accuracy.

- Acrylic (PMMA): Substitute for glass with good rigidity and optical clarity.

- Polycarbonate (PC): Highly transparent with good heat resistance, but susceptible to scratching.

- Polypropylene (PP): High chemical resistance and fatigue strength, but softens at high temperatures.

- ABS: Cost-effective with excellent machinability and impact resistance, but not suitable for high-heat environments.

- Nylon: Versatile with high tensile strength and impact resistance, but not recommended for moist environments.

- UHMW-PE: Exceptional hardness and wear resistance, but thermally unstable during machining.

-

Other Materials: Including foams, wood, and composites, which offer unique properties and applications.

The selection of materials for CNC machining is a critical decision that affects the performance, cost, and success of a project. By considering the machining environment, part weight, heat resistance, electrical conductivity, hardness, surface finish, aesthetics, application, and budget, you can make an informed choice. Unofactpry offers a wide range of CNC machining services and materials, supported by our experienced team and 5-axis machining capabilities, to ensure precision and quality in every project.