Time to read: 6 min

This article delves into the distinctions between laser etching and laser engraving, two advanced manufacturing techniques. We analyze their characteristics in terms of material compatibility, production efficiency, cost-effectiveness, and durability. Through practical application cases, we assess the actual effects of these technologies in different industries, helping readers understand how to choose the appropriate laser marking method for their projects.

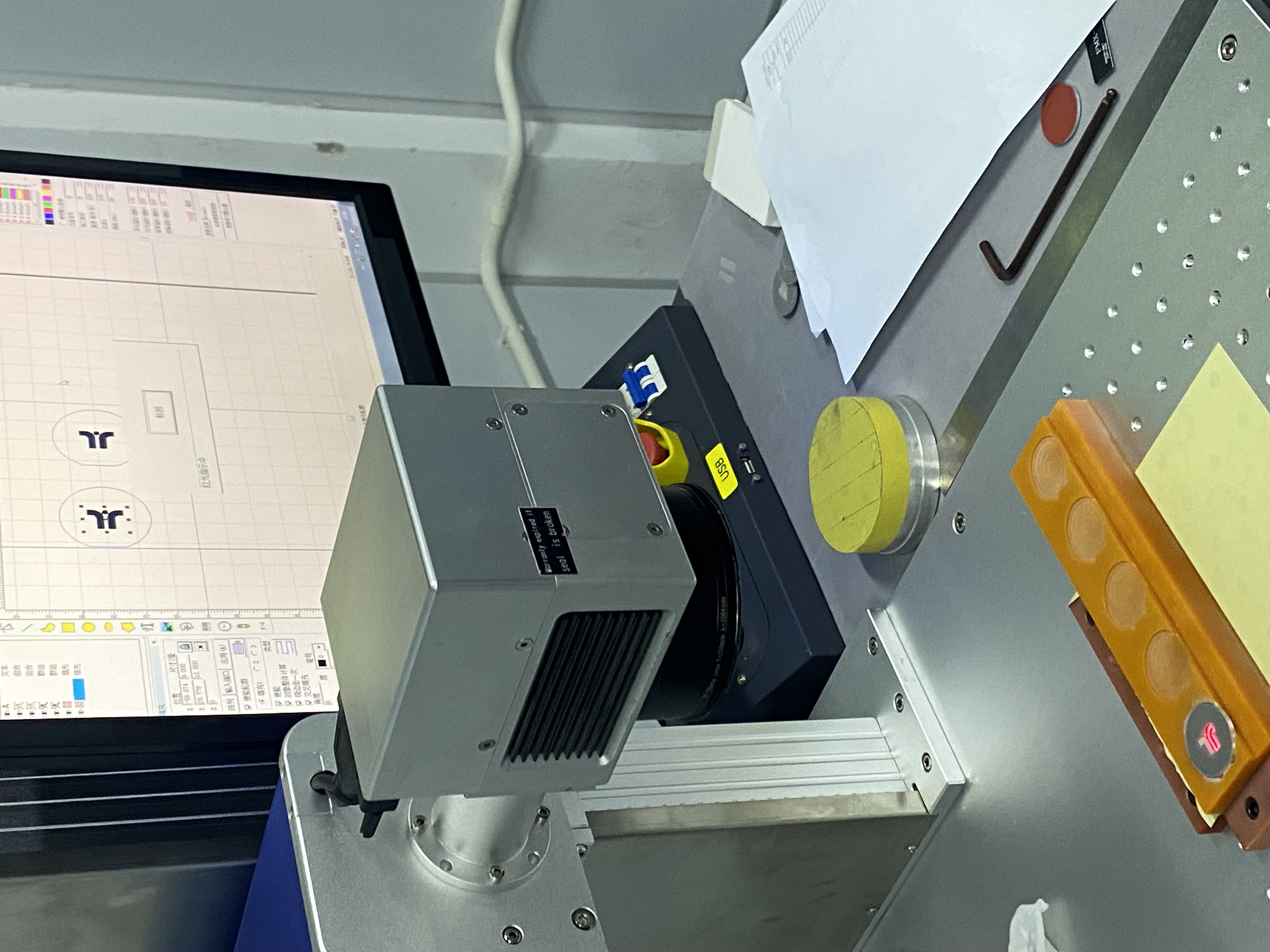

Overview of Laser Etching and Engraving Technologies

In the field of precision manufacturing, laser marking technology has become indispensable due to its speed and accuracy. Laser etching and laser engraving, as forms of laser marking, are often used interchangeably but have distinct differences in their process principles and application effects.

Detailed Explanation of Laser Etching Technology

Laser etching uses high heat to melt and raise the surface of the material, creating a permanent mark. This technique is particularly common on metal materials such as aluminum alloys and stainless steel. Its advantages lie in high precision, fast production, and cost-effectiveness, but it also has the drawback of relatively lower durability.

Detailed Explanation of Laser Engraving Technology

Unlike etching, laser engraving uses a high-energy laser beam to carve deep grooves on the material surface, forming a more durable and tactile mark. This technique is suitable for products that require high durability markings, such as those used in harsh environments.

Comparison of Laser Etching and Engraving

- Depth of Cut: Laser engraving generally has a deeper depth of cut, offering better visibility and durability.

- Production Volume: Laser etching is suitable for high-volume production, while laser engraving is more suitable for small batches or products requiring special markings.

- Cost: Laser engraving is relatively more expensive due to the need for more powerful laser equipment.

Application Fields

Both laser etching and engraving have found their respective application scenarios, from personalized metal accessories to industrial product identification, greatly enhancing the traceability and recognizability of products.

Why Choose Laser Etching or Engraving?

The choice of laser marking technology depends on the specific requirements of the project. Laser etching is suitable for artistic and decorative products, while laser engraving is suitable for products that require long-term durability.

Conclusion

In summary, laser etching and engraving each serve distinct purposes within the manufacturing industry. Laser etching excels in high-volume, cost-effective applications, while laser engraving provides the durability required for long-lasting, tactile markings. The optimal technique depends on factors such as material, production volume, and the desired lifespan of the markings. By carefully considering these variables, manufacturers can leverage the strengths of each method to enhance product quality and traceability.