Time to read: 6 min

Aluminum, with its lightweight, durability, strength, and other properties, has become a top material in several industries, including electronics, automotive, architecture, and aerospace. With the rise of laser cutting technology, the field of aluminum processing has experienced a revolution. This article will explore the process of laser cutting aluminum, its practical applications, and the key factors affecting this process.

What is Laser Cutting?

Laser cutting is a manufacturing process that uses laser beams to cut through a wide range of materials, including plastics, metals, and composite materials. The process involves using a laser cutting machine that generates a highly concentrated and intense laser beam of high heat energy that melts, vaporizes, or burns through the laser cutting material.

Advantages of Laser Cutting Aluminum

Laser cutting aluminum parts is a non-contact process, preventing machine-inflicted damage to the aluminum part surface. This is critical in industries that use aluminum parts for their surface integrity and those that don’t want to spend on surface finishing processes such as powder coating, annealing, etc.

- Non-contact Process: Prevents machine damage to the aluminum part surface, reducing the cost of surface treatment processes.

- Flexibility: Laser cutting is compatible with aluminum alloys of different thicknesses without losing consistency and accuracy.

- Repeatability and Efficiency: The laser cutting process is precise, consistent, and accurate as it is computer-controlled, suitable for high-volume production.

Challenges of Laser Cutting Aluminum

While laser cutting aluminum has many advantages, it also presents some challenges.

- High Reflectivity: The reflective nature of aluminum can cause damage to laser cutting machines.

- Good Thermal Conductivity: Aluminum's rapid heat dissipation can make the cutting process difficult.

- Need for Secondary Machining: Laser cutting aluminum can result in sharp edges and burrs along the cut, necessitating secondary machining for a smooth edge.

Preparation for Laser Cutting Aluminum

A successful laser cutting operation requires a perfect understanding of the process.

- Material Selection and Preparation: Choose aluminum alloys compatible with the process and consider the part's thickness, surface condition, and composition.

- Determining Optimal Laser Cutting Parameters: Including laser power, lens focal length, cutting speed, and beam diameter.

- Fixturing and Positioning of Aluminum Sheets: Ensure that aluminum parts are stable, flat, and secure.

Laser Cutting Techniques for Aluminum

Laser cutting aluminum can be accomplished using various types of lasers, including CO2 lasers, fiber lasers, and YAG lasers.

- CO2 Lasers: Suitable for cutting thick aluminum plates.

- Fiber Lasers: Suitable for cutting thin to medium thickness aluminum plates.

- YAG Lasers: Suitable for cutting thin and medium thickness aluminum plates.

Applications of Laser-Cut Aluminum Parts

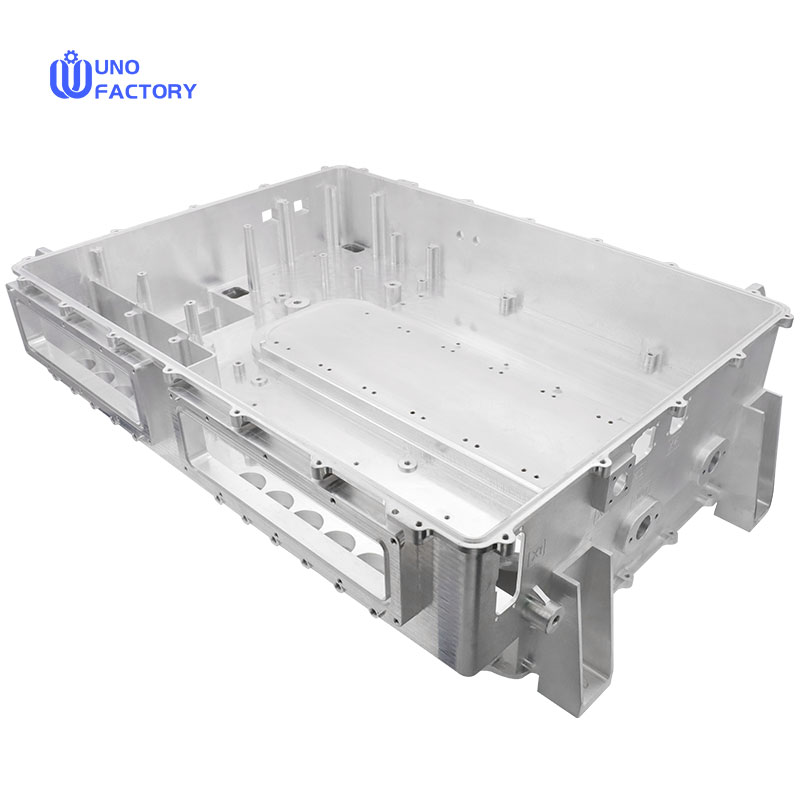

The applications of laser-cut aluminum parts are diverse, including the automotive, aerospace, electronics and electrical industries, industrial machinery, and architecture and construction.

Conclusion: Laser cutting aluminum stands out in the field of aluminum processing for its versatility and precision. Understanding the factors and machines involved in laser cutting is crucial for successful outcomes.

FAQs:

- What’s the best aluminum for laser cutting? Aluminum alloys in the 5000, 6000, and 7000 series are best for laser cutting.

- How much does it cost to laser cut aluminum? Costs range from $10 to $20 per hour, depending on design complexity, material thickness, quantity, and service provider.

- How thick of aluminum can laser cut? The thickness depends on the cutting machine's output power and type.

- What’s the best laser cutter to cut aluminum? CO2 and fiber laser cutters both provide precise and clean cuts, depending on the aluminum part's thickness.

Start Your Aluminum Laser Cutting Services Now: Choose a trusted laser cutting service for precise and customized components. Unofactory offers unparalleled expertise in laser cutting for various industries, providing high-quality results with aluminum and other materials. Let's start your project today!