Time to read: 6 min

In the realm of manufacturing, the choice between cast iron and steel is often crucial. Both metals possess distinct properties that can influence a product's performance and cost. This comprehensive guide explores the differences, advantages, and disadvantages of cast iron and steel, providing insights to aid in material selection for your projects.

Understanding Cast Iron and Steel

Cast iron and steel are金属材料 that have been pivotal in manufacturing due to their strength, durability, and aesthetic appeal. Despite their similar appearances, they exhibit unique characteristics that can significantly impact a production process.

What is Cast Iron?

Cast iron is produced through the smelting of iron-carbon alloys with a carbon content ranging from 2-4%. It is known for its brittleness and various types, including gray iron, white iron, malleable iron, ductile iron, and compacted graphite iron, each resulting from different processing techniques and heat treatments.

What is Steel?

Steel is an alloy of iron with a carbon content typically between 0.15 to 2%. It is stronger and more resistant to breakage than cast iron, and it may also contain other elements such as silicon, manganese, phosphorus, sulfur, and oxygen. Stainless steel, for instance, contains 11% chromium, making it resistant to oxidation and corrosion.

Cast Iron vs Steel: Key Differences

| Attribute | Cast Iron | Steel |

|---|---|---|

| Carbon Content | 2% to 4% | Less than 2% |

| Melting Point | 2200°F | 2500–2800°F |

| Strength | High Compressive | High Tensile |

| Castability | Easy | Less Easy |

| Corrosion Resistance | Higher | Lower |

| Impact Resistance | High | Lower |

| Cost | Cheaper | More Expensive |

| Applications | Pipe fittings, machine parts, etc. | Infrastructure, vehicles, appliances, etc. |

Advantages and Disadvantages of Cast Iron

Advantages:

- Excellent casting ability

- High compression strength

- Good machinability

- Anti-vibration properties

- Wear resistance

Disadvantages:

- Susceptibility to corrosion

- Low tensile strength

- Brittleness

Advantages and Disadvantages of Steel

Advantages:

- Design flexibility through alloying elements

- Enhanced strength

- Corrosion resistance

- Easy machining

Disadvantages:

- Higher cost compared to cast iron

- Less impact resistance

Choosing Between Cast Iron and Steel

The decision between cast iron and steel should be guided by the specific requirements of your product, including strength needed, resistance to corrosion, and cost considerations.

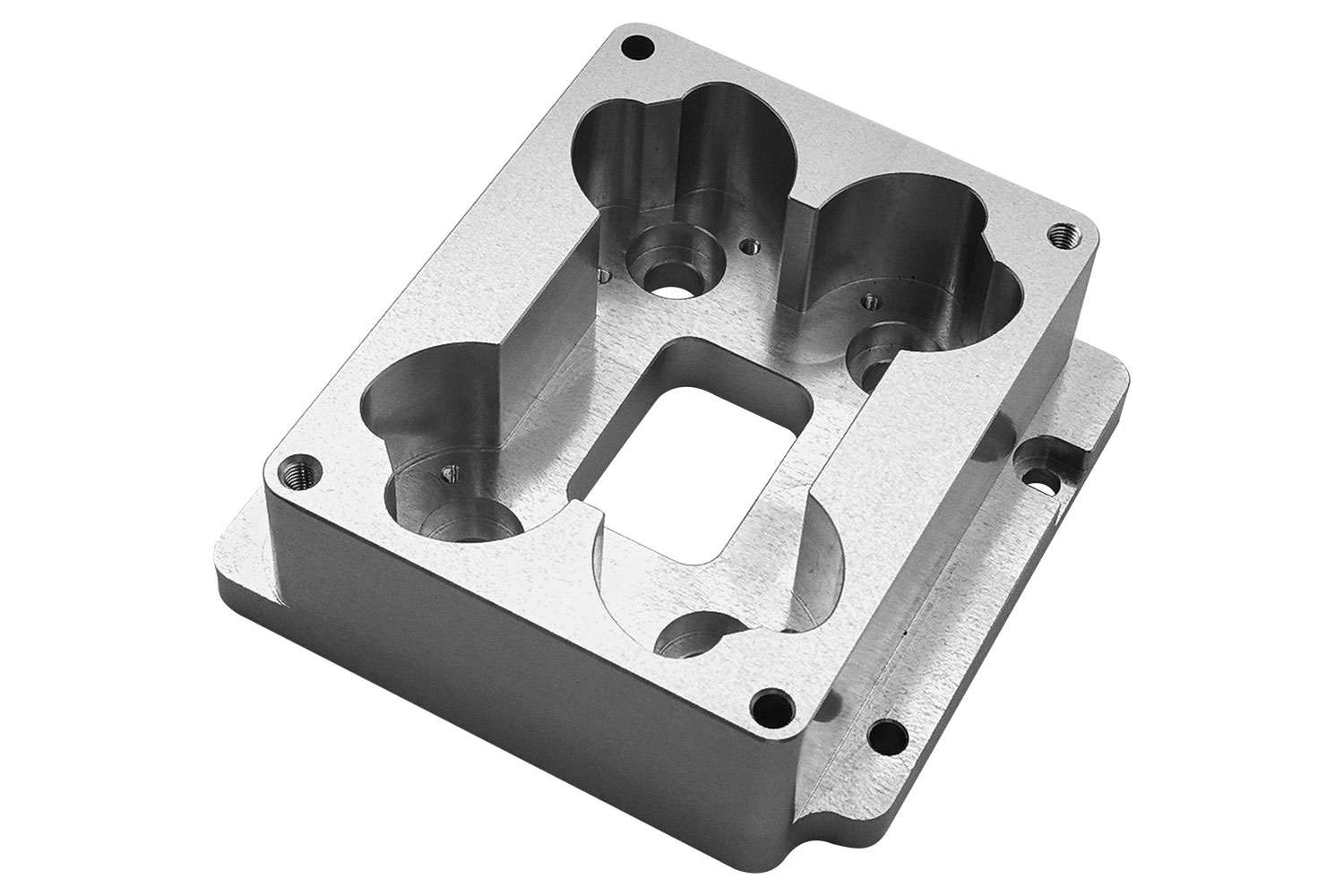

Unofactory: Your Partner for Metal Casting Services

When it comes to sourcing metal parts, Unofactory is your go-to solution for metal casting services. Our expertise in die casting and other casting services ensures the production of high-quality metal parts that meet your exact specifications.

By uploading your project to our platform, you receive an instant quotation and DFM analysis, streamlining your production process. Our commitment to quality and efficiency makes Unofactory the ideal choice for your metal casting needs.

Cast iron and steel serve different applications and offer unique benefits. Understanding their properties, advantages, and disadvantages is essential for selecting the right material for your manufacturing projects. Unofactory is here to guide you through the process, providing expert advice and top-notch metal casting services.