Time to read: 6 min

What Are Tolerances?

Tolerances are the specified limits of dimensional variation that can occur in a manufactured part. In CNC machining, they indicate how much a part's dimensions can deviate from the nominal size and still be considered acceptable.

Common Types of Tolerances in CNC Machining

- Standard Tolerances: Machinists often follow standard tolerances unless specific customer requirements dictate otherwise.

- Bilateral Tolerances: Allow deviations in both positive and negative directions from the nominal dimension.

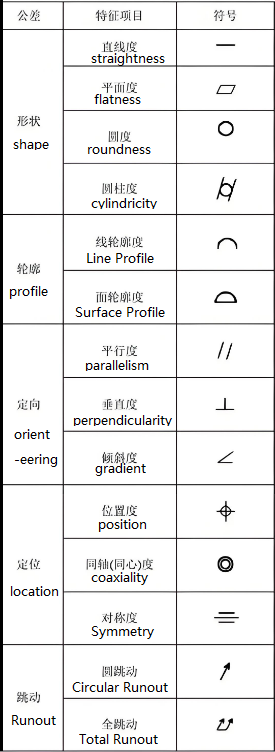

- Geometric Dimensioning and Tolerancing (GD&T): A comprehensive system that defines geometric characteristics and their allowable variations.

- Unilateral Tolerances: Permit deviations in only one direction, either plus or minus.

- Limit Tolerances: Specify a range between an upper and lower limit within which the part's measurement must fall.

Things to Keep in Mind When Choosing Tolerances

- Application of Parts: The intended use of the part will often dictate the required tolerances.

- Cost Implications: Tighter tolerances can increase machining time and costs due to the need for more precise control and potential tool wear.

- Material Characteristics: Different materials affect the achievable tolerances due to factors like hardness, abrasiveness, and heat stability.

- Manufacturing Method: The choice of CNC machine and method can influence the level of tolerance that can be practically achieved.

- Inspection Requirements: Tight tolerances necessitate more rigorous and time-consuming inspections, potentially requiring specialized equipment.

How to Find the Right Tolerance

- Consider the Part's Use: Understand how the part will be used to determine the necessary precision.

- Consult with a Reputable CNC Machining Company: Engage with experts to discuss project goals and determine optimal tolerances.

- Understand the Default Tolerances: Be aware that if tolerances are not specified, CNC services will default to their standard tolerances.

Unofactory: Your Partner for Precision CNC Machining

Unofactory offers CNC machining services with tolerances that align with ISO standards, catering to both standard and extreme precision requirements. Our state-of-the-art facility in Shenzhen, China, houses a range of CNC machines capable of achieving the tightest tolerances while maintaining efficiency.

We provide comprehensive services, including quality inspection, material certifications, and full-dimensional inspections with reports. Our commitment to precision ensures that your parts meet exact specifications.

Conclusion:

Understanding and specifying the appropriate tolerances for your CNC machining project is crucial for balancing quality, cost, and production time. By working with a reliable CNC machining partner like Unofactory, you can ensure that your parts meet the highest standards of precision and functionality.