Time to read: 6 min

Understanding CNC Machining and 3D Printing

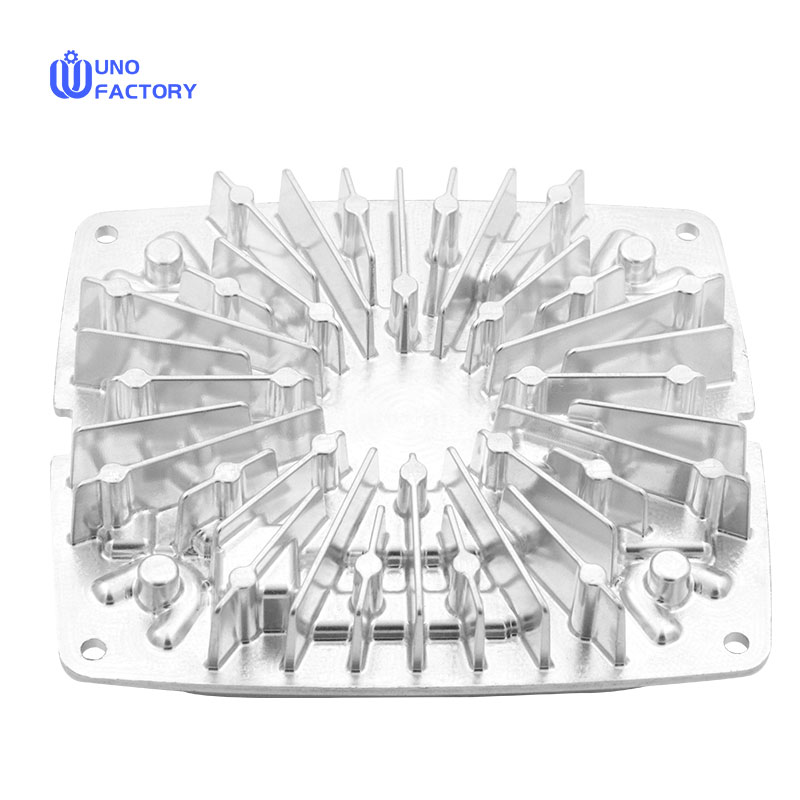

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a block to achieve the desired shape. In contrast, 3D printing, also known as additive manufacturing, builds parts layer by layer by adding material.

Key Differences Between CNC and 3D Printing

Material Selection

- CNC Machining: Ideal for metals and materials that require precise cutting and shaping.

- 3D Printing: Offers versatility with materials ranging from plastics to metals and ceramics.

Production Volume

- CNC Machining: Better suited for high-volume production due to economies of scale.

- 3D Printing: Excellent for low-volume production and rapid prototyping.

Part Size

- CNC Machining: Capable of handling larger parts due to the machine's physical size.

- 3D Printing: May have limitations in part size, depending on the printer.

Complexity of Design

- CNC Machining: Requires expert input to navigate complex designs.

- 3D Printing: Unrestricted by design complexity, ideal for intricate geometries.

Dimensional Accuracy

- CNC Machining: Highly accurate but dependent on operator input.

- 3D Printing: Consistently delivers precise parts with minimal human intervention.

Surface Finish

- CNC Machining: Typically provides a superior surface finish suitable for final products.

- 3D Printing: May require post-processing for a smooth finish.

Production Speed

- CNC Machining: Faster for larger parts and high-volume production.

- 3D Printing: Quicker for small parts and prototypes.

Post-Processing Requirements

- CNC Machining: Minimal post-processing needed for most applications.

- 3D Printing: Often requires additional steps, such as heat treatment for metals.

Eco-Friendliness

- CNC Machining: Generally more material-efficient and may use recycled materials.

- 3D Printing: Can be eco-friendly, depending on the materials and processes used.

Cost Considerations

- CNC Machining: Lower costs at scale but higher upfront investment.

- 3D Printing: Lower initial costs but may be less cost-effective in high volumes.

Choosing Between CNC Machining and 3D Printing

When deciding between CNC and 3D printing, consider factors such as material properties, part complexity, production volume, required precision, surface finish, and overall cost.

Unofactory: Your Partner for Prototyping and Production

Unofactory offers both CNC machining and 3D printing services, ensuring that your prototypes and production parts meet the highest quality standards. Our experienced team and state-of-the-art facilities provide you with reliable and efficient manufacturing solutions.

To get started, upload your design file to our platform and receive an instant quotation. Our online system allows for real-time manufacturing tracking, ensuring transparency and timely delivery.

Conclusion

CNC machining and 3D printing serve different needs in the manufacturing process. By understanding the characteristics and capabilities of each technology, you can make an informed decision that aligns with your project requirements and goals.