Time to read: 6 min

In the realm of surface finishing techniques, bead blasting stands out for its versatility and efficiency. This guide offers an in-depth look at bead blasting, exploring how it works, the materials used, its advantages and disadvantages, and its applications across various industries.

What is Bead Blasting?

Bead blasting is a surface finishing process that utilizes high-pressure projection of fine glass beads to clean or create a smooth, shiny finish on a variety of materials.

How Does Bead Blasting Work?

The process involves a bead blaster that propels bead-shaped media against a surface, leaving a uniform and often satin-like finish. The spherical nature of the media results in a dimpled surface, which is ideal for applications requiring a smooth, uniform appearance.

Tools and Materials for Bead Blasting

To achieve the best bead blast finish, it's essential to use the right tools and materials:

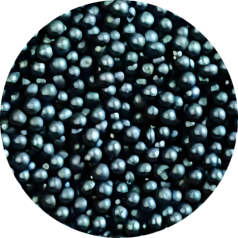

Glass Beads

Made from lead-free, soda-lime glass, glass beads are environmentally friendly and can be recycled multiple times.

Bead Blaster Cabinets

These enclosures are designed to contain the bead blasting process, with features like seamless sealing and view window protection for operator safety and visibility.

Bead Blaster Gloves

Attached to the cabinet, these gloves ensure safety and comfort during the bead blasting process.

Bead Blaster Gun

A critical component for controlling the flow of bead media, with options for foot pedal or trigger operation.

Tips for Achieving the Best Bead Blast Finish

To get the most out of bead blasting, consider the following tips:

- Use low pressure to prevent damage to the beads and the component surface.

- Strip off any rust or oxides before bead blasting to ensure a quality finish.

Pros and Cons of Bead Blasting

Bead blasting offers several benefits, such as safety, environmental friendliness, and suitability for delicate components. However, it may not be ideal for tough materials and may not last as long as other media.

Applications of Bead Blast Finish

Bead blasting is widely used in industries like automotive, aerospace, and medical for applications including peening, deburring, cosmetic finishing, and preparing surfaces for painting or powder coating.

Unofactory’s High-Quality Finishing Services

For professional bead blasting services, Unofactory provides expert assistance and cost-effective solutions tailored to your industry's needs.

Conclusion

Bead blasting is a valuable technique for achieving high-quality surface finishes without altering the dimensions of the part. Whether you're in need of a satin finish, rust removal, or surface preparation, bead blasting offers a versatile and efficient solution.