Time to read: 6 min

This article delves into additive and subtractive manufacturing technologies, analyzing their definitions, application areas, advantages and disadvantages, and exploring their different roles and relationships in modern manufacturing.

-

Introduction: Briefly describe the development background of additive and subtractive manufacturing technologies and their importance in industrial manufacturing.

-

Detailed Explanation of Additive Manufacturing: Introduce the principles, types (Binder Jetting, Directed Energy Deposition, Material Extrusion, Powder Bed Fusion, Sheet Lamination, VAT Photopolymerization, Material Jetting), and application areas of additive manufacturing.

-

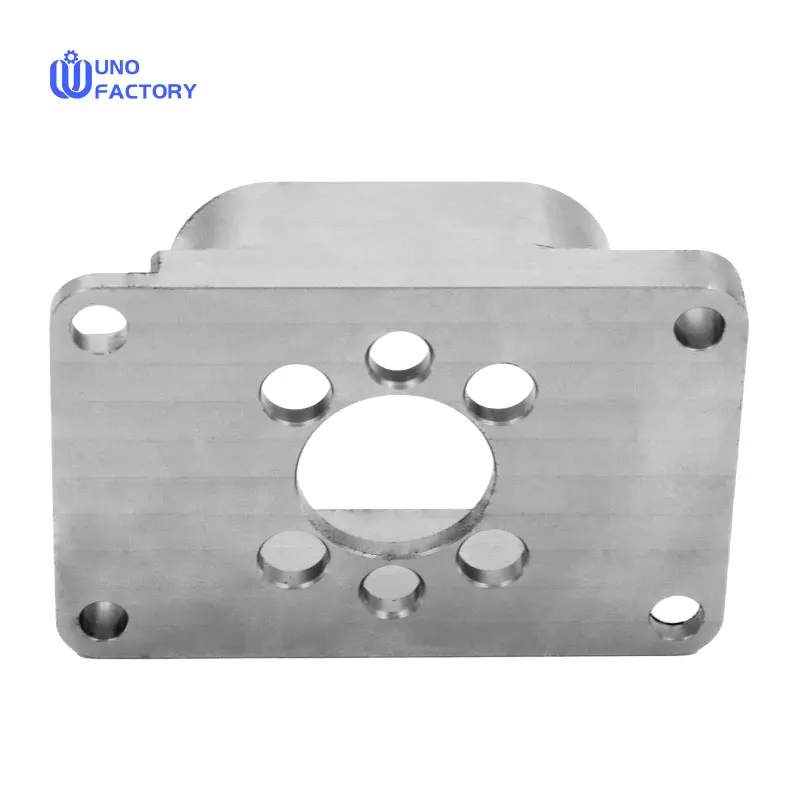

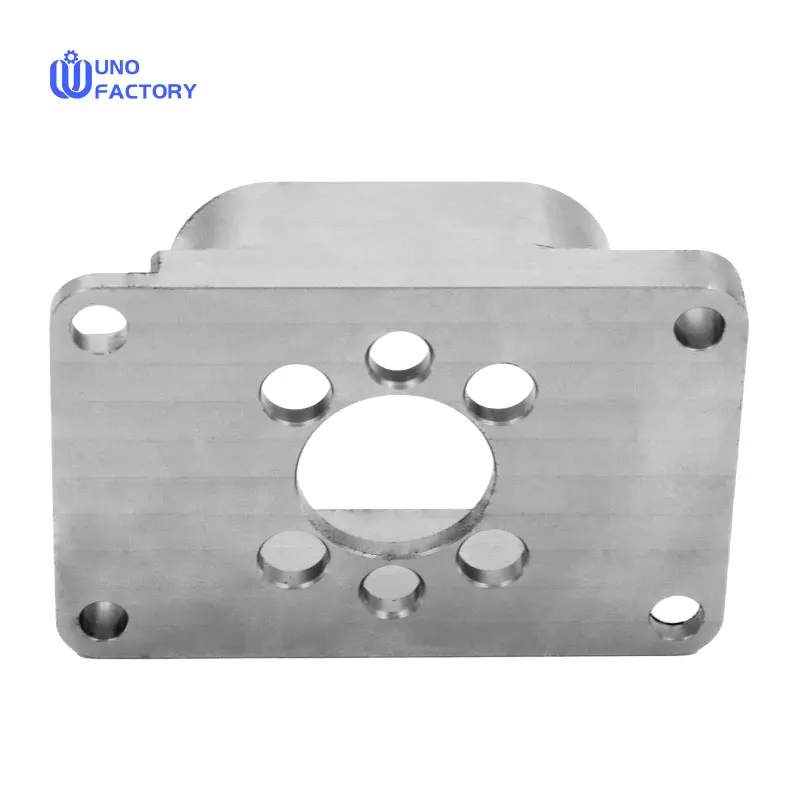

Detailed Explanation of Subtractive Manufacturing: Introduce the principles, types (Laser Cutting, CNC Machining, Abrading, EDM), and application areas of subtractive manufacturing.

-

Advantages and Disadvantages Comparison: Compare the pros and cons of additive and subtractive manufacturing, such as material selection, manufacturing complexity, accuracy, finished part properties, surface finish options, and production speed.

-

Cost Considerations: Discuss the differences in machinery and tooling costs, labor costs, material costs, and post-processing costs between the two manufacturing technologies.

-

Application Case Analysis: Through specific case analyses, demonstrate the practical applications of additive and subtractive manufacturing technologies in different industries.

-

Conclusion: Summarize the characteristics of additive and subtractive manufacturing technologies and how they complement each other based on specific manufacturing needs and goals.