Time to read: 6 min

The stress-strain curve is a pivotal graphical representation that elucidates a material's behavior under tensile stress. This comprehensive guide by Unofactory delves into the mechanics of the stress-strain curve, its significance in material selection, and how it informs engineering decisions for durable and safe structures.

In the domain of mechanical engineering, understanding a material's response to stress is crucial. The stress-strain curve, a graphical depiction of a material's deformation under load, provides critical data for engineers. This guide will explore the curve's components, its interpretation, and its role in assessing a material's mechanical properties.

What is Stress?

Stress is the measure of the force exerted per unit area within a material. It's a fundamental concept that enables engineers to predict the limits of a material's tolerance before failure occurs. The formula for stress is crucial in this context:

\text{Stress} = \frac{\text{Force}}{\text{Cross-sectional Area}}Stress=Cross-sectional AreaForce

The Evolution of the Stress-Strain Curve

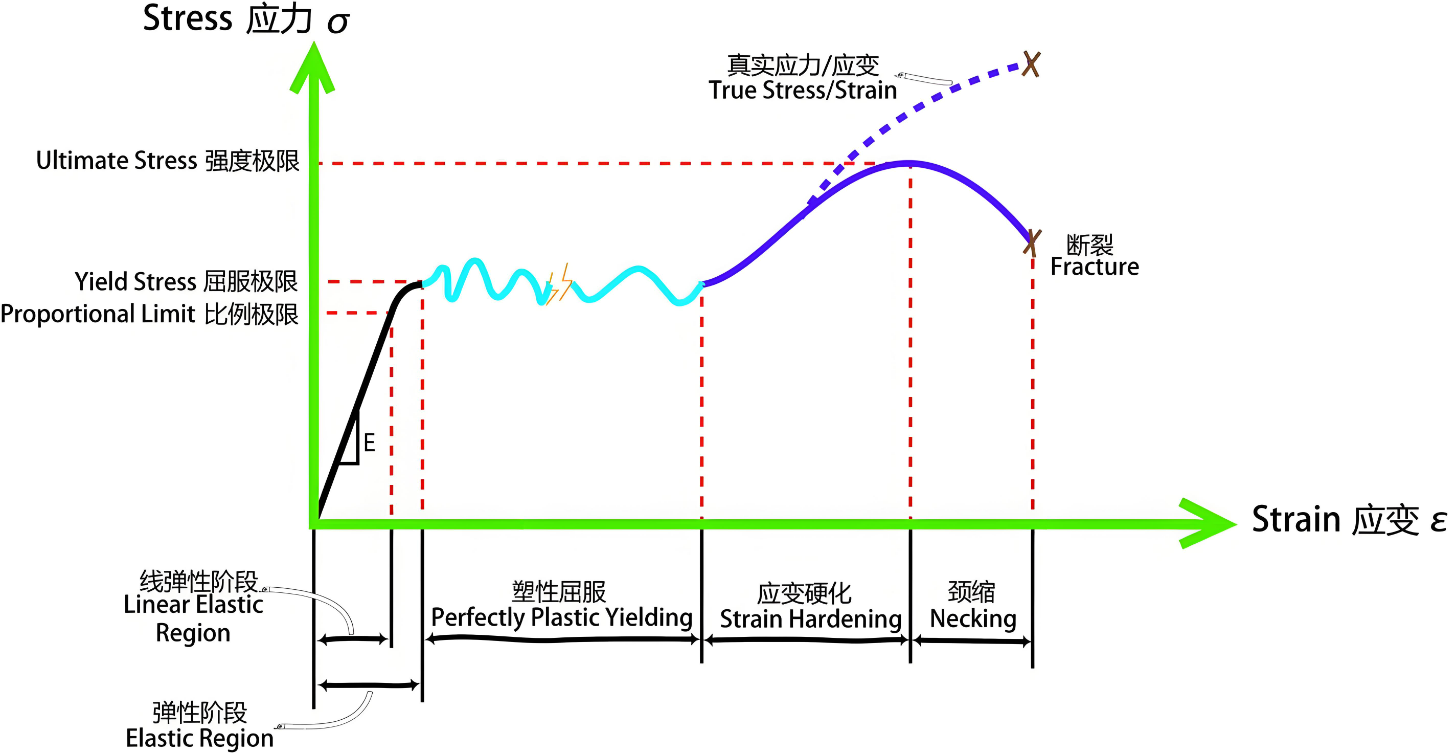

The stress-strain curve evolves through distinct stages, each revealing different aspects of a material's behavior:

1. Elastic Deformation

Initially, the material undergoes elastic deformation, where it returns to its original shape once the stress is removed.

2. Plastic Deformation

Beyond a certain point, known as the yield point, the material enters a phase of plastic deformation, where it does not return to its original shape upon stress removal.

3. Necking and Fracture

The final stage is characterized by necking, where localized deformation leads to a reduction in cross-sectional area, culminating in fracture.

Interpreting the Stress-Strain Graph

Reading a stress-strain graph involves identifying key points that indicate the material's response to stress:

- Proportional Limit: The point where the stress-strain relationship is linear and directly proportional.

- Elastic Limit: The threshold beyond which the material cannot return to its original dimensions.

- Yield Point: The precise point where the material transitions from elastic to plastic deformation.

- Ultimate Stress Point: The peak stress value before the material begins to neck.

- Fracture Point: The point of failure where the material breaks.

The Significance of the Stress-Strain Curve in Material Selection

The stress-strain curve is indispensable for material selection in engineering applications. It helps in determining the modulus of elasticity, yield strength, ultimate strength, and ductility, which are vital for designing safe and efficient structures.

Conclusion:

The stress-strain curve is a fundamental concept in materials science and engineering. It provides a comprehensive view of a material's mechanical behavior under stress, guiding engineers in making informed decisions about material selection and structural design.